LCRR/LCRI Rulemaking Overview

The Environmental Protection Agency (EPA) published the Lead and Copper Rule Revisions (LCRR) on January 15, 2021. The LCRR established a compliance deadline of October 16, 2024 for water systems to complete their initial service line inventories. In addition, it requires annual customer notices to be delivered to persons served by unknown or potential lead service lines and requires systems to distribute Tier 1 public notification to all customers served by the system within 24 hours following a lead action level exceedance.

The EPA published the Lead and Copper Rule Improvements (LCRI) in the Federal Register on October 30, 2024 to further strengthen lead reduction efforts. The LCRI establishes a compliance deadline of November 1, 2027 for systems to comply with various requirements such as submitting an updated service line inventory (baseline inventory), creating a lead service line replacement plan, updating lead and copper sampling plans, a lowered lead action level (lowered from 15 ppb to 10 ppb), and submitting a list of schools and childcare facilities to the state. The LCRI also requires systems to validate certain unknown service lines by 2034 and replace all lead lines by 2037.

The following table provides a summary of some of the key LCRI requirements:

| LCRI Requirement | Deadline | Applicability |

| Customer Notices to Lead or Potential Lead Lines | Annually by November 15th | Systems with service lines classified as “Lead”, “Galvanized Requiring Replacement”, or “Unknown” in their inventory |

| Baseline Inventory with Updates and Connector Material | 11/1/2027 | All Community and Non-Transient Non-Community Systems |

| Lead Service Line Replacement Plan | 11/1/2027 | Systems with “Lead”, “GRR”, or “Unknowns” |

| Updated Sample Site Plan | 11/1/2027 | All Community and Non-Transient Non-Community Systems |

| Revised Lead Action Level (15 ppb > 10 ppb) | 11/1/2027 | All Community and Non-Transient Non-Community Systems |

| Lead Gooseneck Replacements | Ongoing | Beginning 11/1/2027, must replace when encountered during routine work |

| List of School and Daycares to the State | 11/1/2027 | Systems that serve one or more school or daycare |

| School and Childcare Lead Monitoring | Beginning in 2028 | Systems that serve one or more school or daycare |

| Field Validation of Non-Lead Lines | 11/1/2034 | Systems with lines installed pre-1988 that were not field verified |

| Identification/verification of remaining unknowns | 11/1/2037 | Systems with remaining unknowns |

| Systems with remaining unknowns | 11/1/2037 | Systems with Lead or GRR lines |

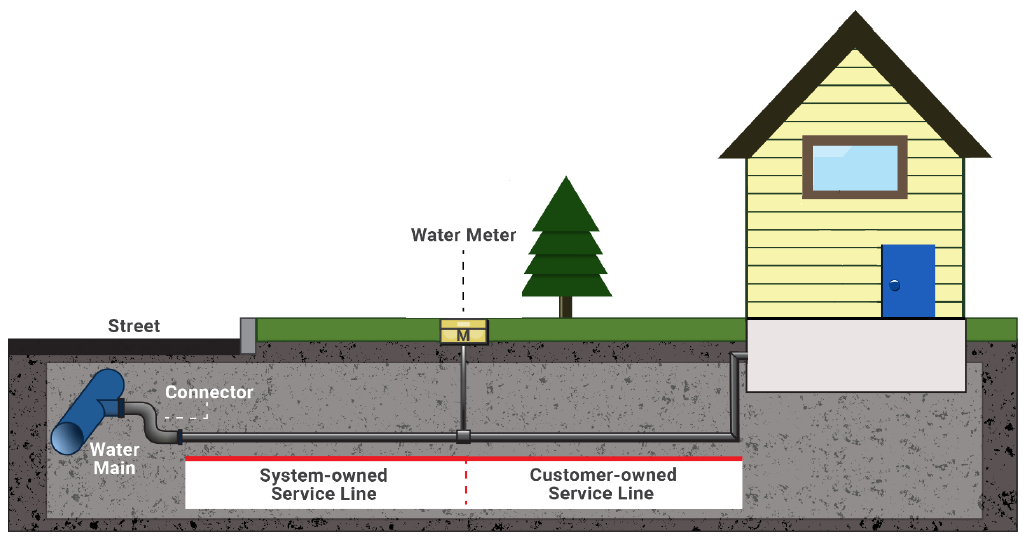

Under the LCRR, EPA required all community water systems (CWSs) and non-transient non-community (NTNC) water systems to develop an inventory of all service line connections, regardless of ownership. Systems were required to submit an inventory of the system-owned and customer-owned portions of all service lines in the system’s distribution system to the Louisiana Department of Health (LDH) by October 16, 2024. For more information on the initial service line inventory requirements, please visit the LDH LSLI website

Under the LCRI, systems must submit an updated service line inventory to the state by November 1, 2027. This updated inventory, referred to as the “baseline inventory”, must include:

-

Any updates to the inventory since the initial service line inventory submittal. This includes new service connections, updated material findings, etc.

-

Service line connector material for each service connection.

What is a “connector”? Under the LCRI, a connector is defined as a short segment of piping, not exceeding two feet, that can be bent and is used for connections between rigid service piping, typically connecting the service line to the main. They are often referred to as goosenecks or pigtails (see illustration below).

NOTE: under the LCRI, the connector material for each service line must be categorized in Column ‘N’ (Service Line Connector) of the LDH Service Line Inventory Template as follows (select from the dropdown menu in the template):

-

Lead – Where the connector is made of lead.

-

Replaced Lead – Where the connector was previously made of lead but has been removed or replaced.

-

Never Lead – Where the connector is determined through an evidence-based record, method or technique not to be made of lead, and there was never a lead connector present.

-

Unknown – Where the connector material is not known.

-

No Connector Present – Where there is not a connector in use such as when the service line is tied directly to the corporation stop without a connector as shown in the following illustration.

Illustration of where a service line-to-main connection is made without a connector.

- LDH Lead Service Line Inventory Submittal Portal User Guide

- LDH Lead Service Line Inventory

- EPA LSLI Development Guidance Manual. The guidance includes best practices, case studies for inventory development and detailed information on various lead service line identification methods and techniques. https://www.epa.gov/ground-water-and-drinking-water/revised-lead-and-copper-rule.

Within 30 days of completion of the initial lead service line inventory, all water systems must inform all persons served by the water system at the service connection with a “lead”, “GRR”, or “lead status unknown service line”. The notice must be provided by mail, hand delivery or by another method approved by the State. The notification must be repeated on an annual basis (by November 15th each year) until the entire service connection is no longer a “lead”, “GRR”, or “lead status unknown service line” service line.

Systems have until July 1 each year to certify to LDH that the previous year’s customer notices were delivered. Systems that completed the customer notices must submit a completed Customer Notice Certification Form to LDH along with a copy of one of the notices distributed to their customers served by a lead, GRR and/or unknown service line.

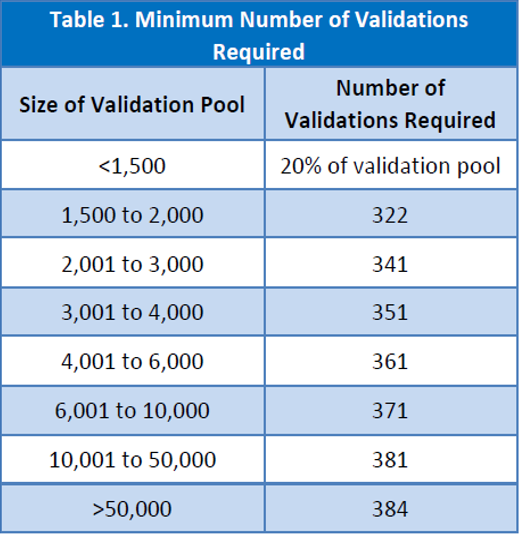

Under the LCRI, systems must validate certain “non-lead” lines by 2034. The general process is as follows:

Step 1: Identify the validation pool. The validation pool consists of all non-lead service lines in the inventory excluding lines installed after the lead ban of 1988, and lines that were visually verified.

Step 2: Determine the minimum number of validations required. See Table 1.

Step 3: Randomly select service lines to be field validated. Water systems can use tools such as a random number generator to ensure the sites are truly randomly selected.

Step 4: Field verify the randomly selected locations. Where ownership of the service line is split, one verification point is required on each side of the meter (i.e., public and private).

Step 5: Submit field verification results to the State. Field verification findings shall be documented and submitted to the state upon completion. If a water system identifies a lead or GRR service lines during validation, water systems must notify the state within 60 Days.

For more information, download the EPA Inventory Validation Technical Fact Sheet at: https://www.epa.gov/system/files/documents/2024-10/final_lcri_fact-sheet_validation.pdf

- A description of a strategy to identify the material composition of all unknown service lines in the inventory.

- A standard operating procedure for conducting full service line replacement.

- A communication strategy for informing customers before a full or partial lead or GRR service line replacement.

- A procedure for customers to flush service lines and plumbing following a disturbance or LSL replacement.

- A strategy to prioritize service line replacement based on factors such as known lead and GRR lines and community-specific factors.

- A funding strategy for conducting replacements that includes ways to accommodate customers that are unable to pay to replace the portion of the service line they own.

- A communication strategy to inform consumers and customers about the replacement plan and program.

- Identification of any laws, regulations, and/or water tariff agreements that affect the water system’s ability to gain access to conduct full replacement.

- For water systems that identify any lead-lined galvanized service lines in the inventory, a strategy to determine the extent of their use in the distribution system.

NOTE: Lead gooseneck connectors are not considered lead service lines so there is not a compliance deadline of when they have to be replaced. However, under the LCRI systems must replace any system-owned lead connectors when encountered during planned or unplanned water system infrastructure work (i.e., when they are exposed). Upon replacement of any gooseneck, pigtail, or connector that is attached to a lead service line, the water system must provide the homeowner:

- information about the potential for elevated lead levels in drinking water as a result of the disturbance,

- an NSF approved pitcher filter or POU treatment device certified to reduce lead,

- Instructions to use the filter, and six months of filter replacement cartridges.

For additional information, please download the EPA Technical Fact Sheet on Lead Service Line Replacements at: https://www.epa.gov/system/files/documents/2024-10/final_lcri_fact-sheet_service-line-inventory.pdf

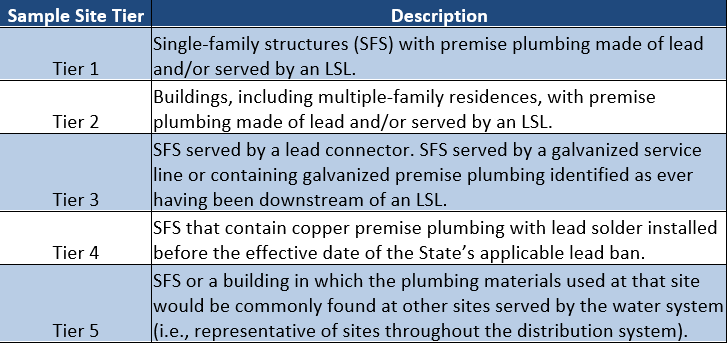

Under the LCRI, systems must reevaluate the sites used for lead and copper monitoring. Updated sample plans required to be submitted to the state by November 1, 2027. The sites must be selected using the updated LCRI Tiering criteria based on which sampling sites have the greatest likelihood of capturing lead levels at the tap (see Table below).

Systems must identify locations in the site sample plan by selecting from sites in the highest tier, unless the site has been found to be unavailable.

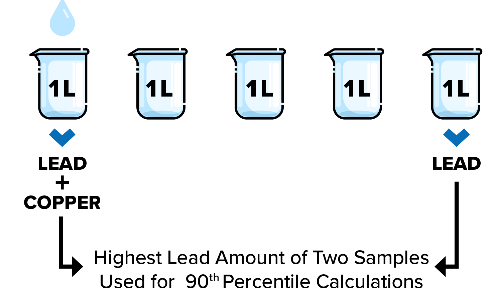

Under the LCRI, water systems are required to collect first and fifth-liter tap samples at sites with lead service lines (this will not affect systems that have no lead service lines). Both the first and fifth-liter samples must be shipped to the LDH/OPH Laboratory to be analyzed for lead and the higher of the two values is used for compliance.

First and Fifth-liter sample collection procedure:

- Fill the first numbered wide-mouth sample bottle with tap water.

- Immediately slide the second bottle under the tap without turning the water off and repeat the process for bottles three through five in consecutive order.

- The following video describes the process in more detail: https://www.youtube.com/watch?v=PQ2E3ht4Iqs

- Find and Fix – Requires systems to collect a follow-up sample at each location with lead > 10 ppb within 30 days of learning of the results. Conduct WQP monitoring at or near the site > 10 ppb. Systems must determine if a “fix” is needed (e.g., adjustment to CCT, flushing portions of the distribution system, or other strategies).

- 90th Percentile Action Level Exceedance – When more than 10 percent of a systems routine lead sample results exceed the action level, systems are required to:

- inform the public within 24 hours (Tier 1 Public Notice) and conduct public education.

- install or adjust corrosion control treatment to reduce lead that leaches into drinking water.

- under the LCRI, systems are required to make filters certified for lead reduction available to all consumers if they have three or more 90th lead action level exceedances (above 10 ppb) within a 5-year time period.

All CWSs must develop and maintain a list of schools and child care facilities they serve and submit it to the State by November 1, 2027.

Starting in 2028, water systems must sample at least 20% of elementary schools and childcare facilities that they serve each year for the first five years. Under the rule, a minimum of 5 samples are required per school and 2 samples per daycare (1st Draw, 250 mL bottles.). Sample results, public education and remediation options must be provided to each sampled school or daycare.

After this initial phase, sampling is typically only required upon request from the school or childcare facility.

See EPA's Technical Fact Sheet: Lead in Schools and Child Care Facilities: https://www.epa.gov/system/files/documents/2024-10/final_lcri_fact-sheet_schools-and-child-care.pdf

Louisiana is eligible to receive over $42 million per year over the next 3 years in dedicated funding for Lead Service Line (LSL) identification and replacement. This funding is part of the Bipartisan Infrastructure Law (BIL) signed by President Biden on November 15, 2021. Any project funded under this appropriation involving the replacement of a lead service lines must replace the entire lead service line (both public and private owned portions), unless a portion has already been replaced or is concurrently being replaced with another funding source.

Under the BIL, 49% of funds awarded to a LSL replacement project would be in the form of grants or principal forgiveness (free) and 51% would be in the form of no-interest loans (up to 30 year terms). Funding for this program will be managed by the Louisiana Revolving Loan Fund Program. For a project to be eligible for funding, it must be otherwise DWRLF eligible. For information on how to apply, please contact the DWRLF program at 225-342-7499.

EPA Links

- EPA Guidance on Developing Lead Service Line Inventories and Service Line Inventory Template: https://www.epa.gov/ground-water-and-drinking-water/revised-lead-and-copper-rule.

- EPA Lead and Copper Rule Improvements (LCRI): https://www.epa.gov/ground-water-and-drinking-water/lead-and-copper-rule-improvements

- EPA Lead and Copper Rule Revisions (LCRR): https://www.epa.gov/dwreginfo/lead-and-copper-rule-implementation-tools

- Federal Register - Final Lead and Copper Rule Revisions (LCRR): https://www.ecfr.gov/current/title-40/chapter-I/subchapter-D/part-141/subpart-I

- Federal Register – Final Lead and Copper Rule Improvements (LCRI): https://www.epa.gov/ground-water-and-drinking-water/lead-and-copper-rule-improvements

- EPA’s LCRI Questions and Answers: https://www.epa.gov/ground-water-and-drinking-water/lcri-questions-and-answers EPA LCRI Webinar: https://www.youtube.com/watch?v=ecN38LOlO5o

- EPA LCRI Technical Fact Sheets: https://www.epa.gov/dwreginfo/lead-and-copper-rule-improvements-supporting-materials

- Tap Monitoring Requirements

- Service Line Inventory & Replacement Requirements

- Public Education and Customer Notice Requirements

- Inventory Validation

- Schools and Childcare Sampling

Contact

If you have questions about the inventory, contact any of the following LDH staff:

Jeremy Harris, P.E.

Compliance Engineer

(225) 342-7471

[email protected]

Vijai Elango, P.E.

Chemical Compliance Engineer

(225) 964-0850

[email protected]

Sean Nolan, P.E.

SDWP Compliance Engineer

(225) 342-7495

[email protected]

Caryn Benjamin,P.E.

Deputy Chief Engineer of Compliance & Enforcement

(225) 342-6157

[email protected]

Official Louisiana State Websites use .la.gov

Official Louisiana State Websites use .la.gov  Secure .gov websites use HTTPS

Secure .gov websites use HTTPS